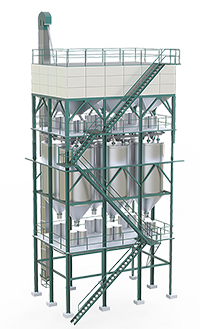

Parboiling

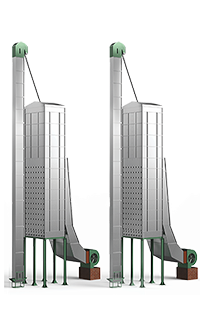

Drying

Elevators

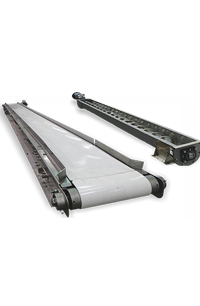

Conveying

Storage Bin

Turnkey

Elevate Your

Business -

Boost Your

Profits

A Safe Investment

The decision to invest in a new Parboiling and Dryer Plant, you can rest assured to us that your plant will fulfill your every need, both in regard to capacity and quality of Rice.

Risk-free Storage

Paddy dryers quickly reduce the moisture content of the freshly harvested Paddy to safe levels and allow for its longterm storage.

Flexibility for the Millers

Millers are free to decide when to carry out drying whatever the weather conditions and to sell the grain when the market price is most favourable.

Increased value

Uniform Parboiling Process & drying makes the grains having uniform colour, low crackle ratio and high germination rate. This improves the quality of the end product and therefore its market value.

Return on the Investment

The key to maximizing return on investment for grain drying equipment is the machines operational design life. Our Parboiling and Dryer plant have many engineering features that ensure durability and long-term performance, efficient Drying, robust Stainless steel.

Technical

Advice

Get free technical advice from our engineers for various applications and specifications.

Widest Range

of Products

Get complete solution for your output, timing, colouring, processing, requirement covering all details concerned to cereal industry.

Demonstration

See the performance of our products in various sites before purchasing.

Training

at Site

Detailed training to your operator to obtain high productivity and innovative methods of working for simpler and faster results.

Equipment Design

Based on customer demand, our expert team prepare detailed drawing of each section.

Civil

Guidance

We produces joint solutions for its customers in cooperation with professional experts, civil and construction engineers.